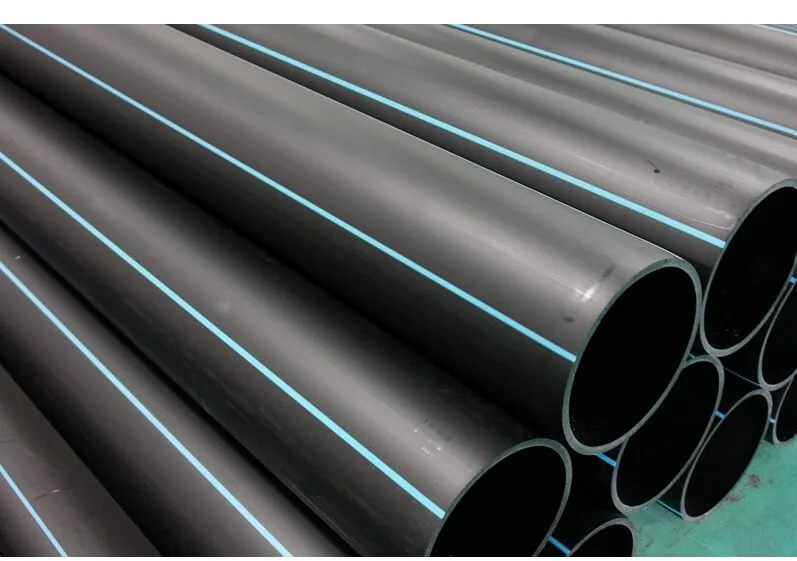

HDPE pipe full form is High-Density Polyethylene pipe. It is a type of plastic pipe that is made from high-density polyethylene, a type of polymer. HDPE pipe is known for its durability, flexibility, and resistance to corrosion. It is also lightweight and easy to install.

HDPE pipe used for

Water supply: Pipe is a popular choice for water mains and distribution pipes. It is resistant to corrosion and chemicals, making it ideal for use in transporting potable water.

Gas distribution: Pipe is also used for gas distribution pipelines. It is resistant to chemicals and can withstand high pressures, making it a safe and reliable option for transporting natural gas.

Sewerage and drainage: Pipe is used for sewerage and drainage systems. It is resistant to corrosion and can withstand high pressures, making it a safe and durable option for transporting wastewater.

Stormwater drainage: Pipe is also used for stormwater drainage systems. It is resistant to corrosion and can withstand high flows, making it a safe and reliable option for transporting stormwater.

Industrial applications: Pipe is used in a variety of industrial applications, including:

· Chemical transportation

· Oil and gas transportation

· Mining

· Agricultural irrigation

· Fire protection

Trenchless installation: this pipe is well-suited for trenchless installation methods, such as horizontal directional drilling (HDD). This can save time and money, and it can also reduce the environmental impact of the project.

This pipe is a versatile and durable pipe material that can be used for a variety of applications. It is resistant to corrosion and chemicals, making it a safe and reliable option for transporting a variety of fluids. HDPE pipe is also lightweight and easy to install, making it a cost-effective choice for many projects.

how is hdpe pipe most commonly joined

HDPE is most commonly joined using heat fusion methods. This method involves heating two HDPE pipe surfaces to a specific temperature, then the pipe cools, and it creates monolithic, permanent, and leak-free pipe joints.

There are two main types of heat fusion methods for joining HDPE pipe:

Butt welding: This is the most common method of joining HDPE pipe. The ends of two pipes are heated and then brought together under pressure. The heat and pressure melt the plastic, forming a permanent joint.

Electrofusion welding: This method uses electrical energy to heat the plastic in a fitting. The fitting is then placed over the end of a pipe, and the electrical current is applied. The heat from the electrical current melts the plastic, forming a permanent joint.

Other methods of joining HDPE pipe include:

Mechanical joints: These joints use compression or flanges to join two pipes. They are not as strong as heat fusion joints, but they are easier to install.

Socket fusion: This method uses a socket fitting to join two pipes. The end of one pipe is inserted into the socket, and then the socket is heated. The heat melts the plastic, forming a permanent joint.

The best method for joining HDPE pipe will depend on the specific application and the site conditions. For example, butt welding is the most common method, but it may not be suitable for applications where the pipes are buried in the ground. In these cases, electrofusion welding may be a better option.

Advantages of HDPE pipe

Durability: HDPE is very durable and can withstand a wide range of temperatures and pressures. It is also resistant to corrosion and chemicals, making it ideal for use in harsh environments.

Flexibility: Pipe is flexible and can be bent on site, which makes it easy to install in difficult or confined spaces.

Lightweight: HDPE pipe is lightweight, which makes it easy to transport and handle.

Cost-effectiveness: HDPE pipe is a cost-effective option for a variety of applications.

Corrugated HDPE pipe

Corrugated HDPE pipe is a type of plastic pipe that is made from high-density polyethylene (HDPE). It has a corrugated outer wall and a smooth inner wall. The corrugated outer wall provides strength and flexibility, while the smooth inner wall reduces friction and allows for a smooth flow of fluids.

Corrugated HDPE pipe is a versatile and durable pipe material that can be used for a variety of applications. It is resistant to corrosion and chemicals, making it a safe and reliable option for transporting a variety of fluids. Corrugated HDPE pipe is also lightweight and easy to install, making it a cost-effective choice for many projects.

Overall, HDPE pipe is a versatile and durable pipe that is well-suited for a variety of applications. It is more durable than PVC pipe and is resistant to a wider range of chemicals and temperatures. HDPE pipe is also lightweight and cost-effective, making it a good choice for many projects.